Fully Automatic Potato Chips Production Line

Product Details:

- Feeding System Automatic

- Frequency 50 Hertz (HZ)

- Automation Grade PLC

- Power Source Electric

- Operating Temperature 180-190 Celsius (oC)

- Machine Type Fryer

- Noise Level 48-58 db

- Click to View more

Fully Automatic Potato Chips Production Line Price And Quantity

- 1 Piece

- 2950000.00 - 4500000.00 INR/Piece

- 15000000.0 INR/Piece

Fully Automatic Potato Chips Production Line Product Specifications

- 180-190 Celsius (oC)

- Other

- Yes

- Electric

- PLC

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- 50 Hertz (HZ)

- 1 Year

- Automatic

- Automatic

- Industrial

- Food Processors

- Free Stand

- Yes

- 55 x 20 Foot (ft)

- Stainless Steel

- Electric Horsepower (HP)

- Other

- Variable

- Automatic

- PLC Control

- Three

- 48-58 db

- 100/200/300/500 Kg /Hrs Kg/hr

- 15 Long Ton

- Fryer

- 220 Volt (v)

Fully Automatic Potato Chips Production Line Trade Information

- Cheque

- 2 Piece Per Month

- 130 Days

- Yes

- Contact us for information regarding our sample policy

- Africa, Asia

- All India

Product Description

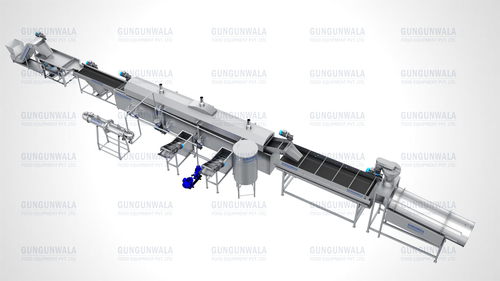

Gungunwala offers Fully Automatic Potato Chips Production Line is a modern, high-efficiency system designed to produce premium-quality potato chips and wafers on an industrial scale. This line automates every stage of the process from potato washing and peeling to slicing, frying, flavouring, and packaging ensuring uniform taste, crispness, and quality.

Built with food-grade stainless steel and advanced automation controls, this line minimizes labour costs, reduces oil consumption, and delivers consistent product quality for continuous operation.

Main Features

- Fully Automatic Operation: Continuous and seamless processing from raw potato to finished chips.

- High Productivity: Suitable for medium to large-scale manufacturing.

- Uniform Quality: Consistent frying, thickness, and flavour across all batches.

- Energy Efficient: Low oil and power consumption with optimized heating systems.

- Hygienic Design: Constructed entirely from SS 304 stainless steel for easy cleaning and durability.

- User-Friendly Controls: PLC-based control panel with automatic temperature and speed adjustment.

Processing Flow:-

1. Hopper with Belt-Elevator-Input of Raw material

2. Rotatory Potato Grader Separating unfit and low quality potatoes.

3. Water Based Screw De-Stoner cum Washer-Removing Stone from Potatoes.

4. Roller Type Continuous Potato Peeler- Removing Peel Of Potatoes

5. Inspection Belt with Wastage Disposal Space-Belt ware manual Inspection of each potato will be executed.

6. Potato Singulator - Separating each Potato before inserting it into Slicer. This helps in avoiding jamming of Slicers mouth and decrease tearing of slices.

7. Slicer- Sliced the Peeled potatoes.

8. Slice Washing Drum (De-Starch Unit, Stage-1)-Drum used to clean each Slice of Potato one by one.

9. Slice Washing Vibrator (De-Starch Unit, Stage-2)- Vibrator used to Clean each Slice of Potato one by one.

10. Screw Type Blancher- Used to remove Excess Sugar from Potato Slices.

11. Dewatering Vibratory Shaker With Air Knife- Removing Surface Water from Chips Slices.

12. High-Speed Belt Specifications- Used to throw each slices into the fryer separately at high speed, [This avoids localize temperature drop within fryer]

13. Automatic Fryer Specifications- 20 ft x 42 inches Plain Chips, Ruffles Chips, and Potato Sticks.

14. Oil Filter Specifications- Continuous Belt Micro Filter.

15. Oil Storage Tank Specifications-1500 Ltrs.

16. Motor & Pump Specifications- Air cooled, Carbon Seal, Crompton-7.5 HP.

17. Control Panel Board Specs- PLC-HMI.

18. De-Oiling and Cooling Conveyor Belt-10 feet x 42 inch.

19. Masala Hopper (Spice Feeder) with Scarf Feeder- SS 304.

20. Online Masala Tumbler-7 feet.

Parameter Specification

Capacity - 100 kg/hr 500 kg/hr

Material of Construction - SS 304 Food Grade

Heating Source - Diesel / LPG / Natural Gas / Thermic Fluid

Power Requirement - 30 100 HP (as per capacity)

Oil Temperature - 150C 190C

Control System - PLC + Touch Screen Panel

Oil Filtration - Continuous Filtration System

Fryer Type - Continuous Conveyor Fryer..

Applications:-

Salted Potato Chips

Masala Potato Chips

Plain & Rippled Wafers

Flavored Potato Chips

Advantages:-

High production efficiency and product uniformity

Minimal oil absorption and wastage

Low labor cost with easy operation

Consistent quality and long shelf life

Hygienic and fully automated system

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fully Automatic Chips Frying Line' category

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese