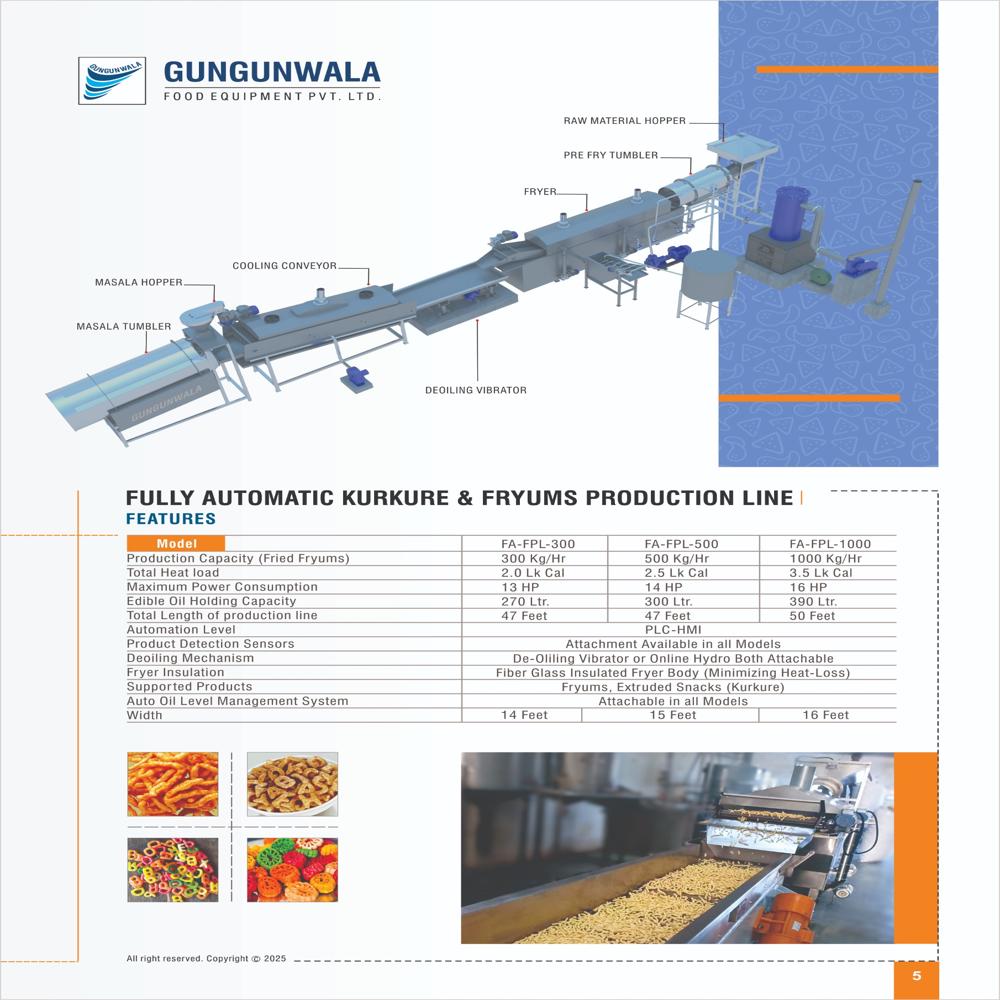

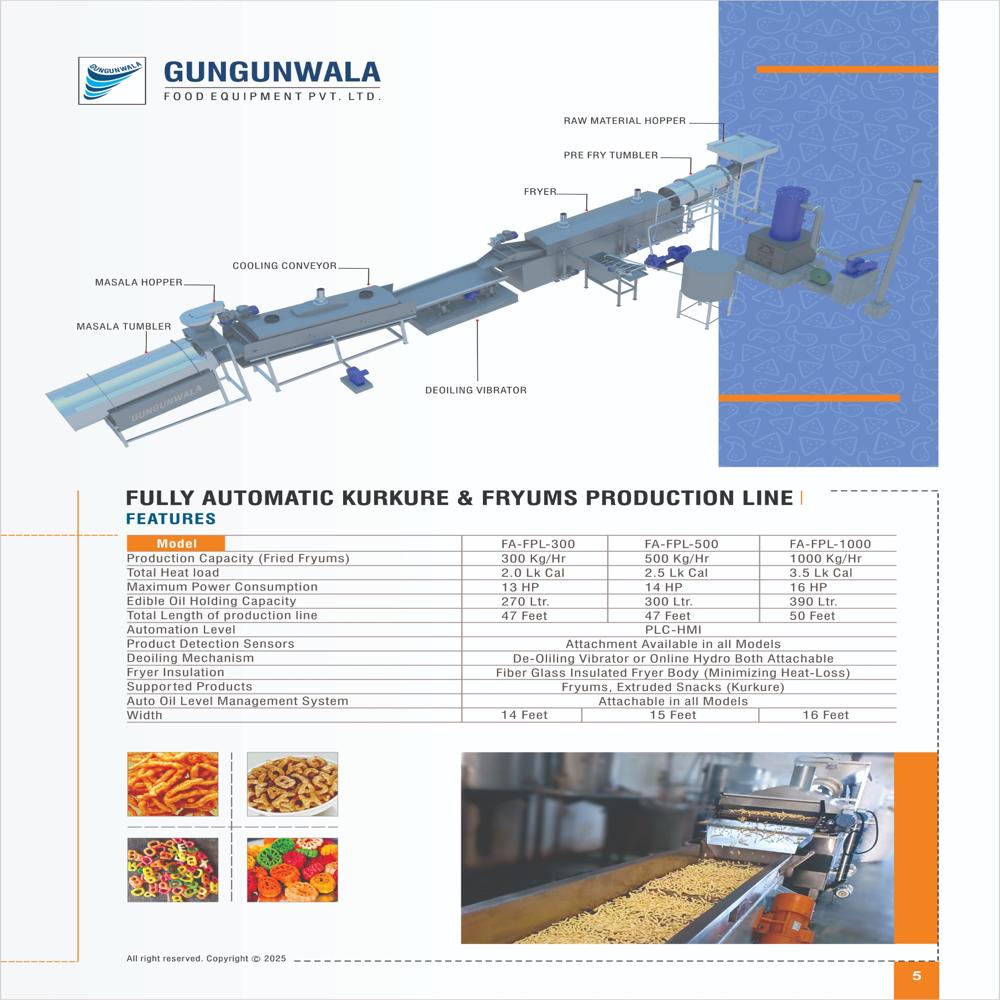

Fully Autoamtic Fryums Frying Line

Product Details:

- Noise Level 58 db

- Power Source Electric

- Operating Temperature 220 Celsius (oC)

- Speed Mode Variable

- Features Automatic

- Phase 3

- Machine Type Automatic Fryer

- Click to View more

Fully Autoamtic Fryums Frying Line Price And Quantity

- 3200000.0 INR/Unit

- 1 Number

Fully Autoamtic Fryums Frying Line Product Specifications

- Variable

- 220 Celsius (oC)

- 300 Kg/hr

- Electric

- 58 db

- 440 Volt (v)

- Stainless Steel

- Frying

- Yes

- Automatic Fryer

- 3

- Automatic

- ECO Friendly, Low Noice, Compact Structure, High Efficiency, Lower Energy Consumption

- Food Processors

- 50 Hertz (HZ)

- 16 Horsepower (HP)

- Free Stand

- Yes

- Automaticc

- Industrial Fryer

- Other

- PLC Control

- 47*12 Foot (ft)

- Automatic

- Diesel,Gas,Pellet,Wood and Thermic

- 10 Tonne

Fully Autoamtic Fryums Frying Line Trade Information

- 70 Days

Product Description

Gungunwala Food Equipment Pvt.Ltd. is a leading manufacturers of Fully Automatic Fryums Frying Line an industrial system designed for the automated production and frying of pellet snacks, such as Fryums, 3D snacks, and shaped pellet products. These systems are widely used in the snack food industry for their ability to handle large volumes, provide consistent product quality, and reduce manual labour.

Key Features of Fully Automatic Fryums Frying Line.

Output capacities range from 100 to 1,500 kg per hour, with common models supporting 300 kg/hr, 500 kg/hr, 1,000 kg/hr, and even higher.

Construction primarily in food-grade stainless steel (often AISI SS-304) for hygiene and corrosion resistance.

Multiple heating options available, including diesel, gas, LPG, wood, thermic fluid.

Integrated systems typically include pellet feeding elevator, pre-fryer, main fryer with submerger/conveyor belts, de-oiling conveyor, and vibratory billet screen for debris removal.

Automatic oil temperature control and inline oil filtration systems support consistently high product quality and extended oil life.

Modular design allows for the addition of blanchers, flavouring stations, and packaging units for a turnkey snack line.

Operational Flow of Fully Automatic Fryums Frying Line.

Pellets are loaded into a hopper and elevated by a conveyor to the fryer.

Main fryer uses submerger and conveyor belts to ensure even frying and prevents floating, ending to uniform colour and crispness.

Products pass through a de-oiling conveyor to remove excess oil prior to cooling seasoning, and packing.

Advantage and Applications of Fully Automatic Fryums Frying Line.

Continuous high-capacity production, ideal for commercial snack manufacturers.

Consistent oil management and temperature control deliver uniformity and improve product shelf-life.

Designed for snack pellet varieties, such as Fryums, rings, 3D shapes, and both plain and coated products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fully Automatic Pellet Frying Line' category

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese